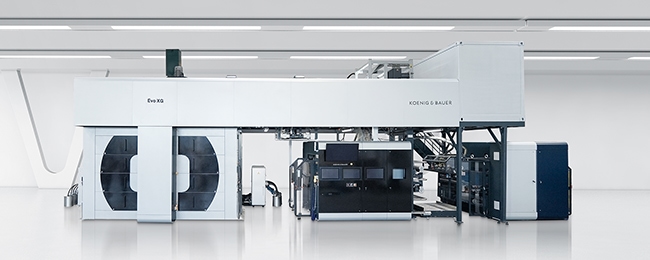

Sheetfed Offset

- DriveTronic feeder with peerless dedicated drive technology

- Bleed- and wear-free ink ducts

- Energy-efficient VariDry drying systems, right up to LED-UV

- Non-stop pile changing solutions for uninterrupted production

OMEGA Intro series is specifically designed as a high quality budget line to be a reliable profit center for many years to come. Like all Koenig & Bauer Duran Folder Gluers, the OMEGA Intro line is designed and manufactured at Koenig & Bauer Duran plant in Istanbul.

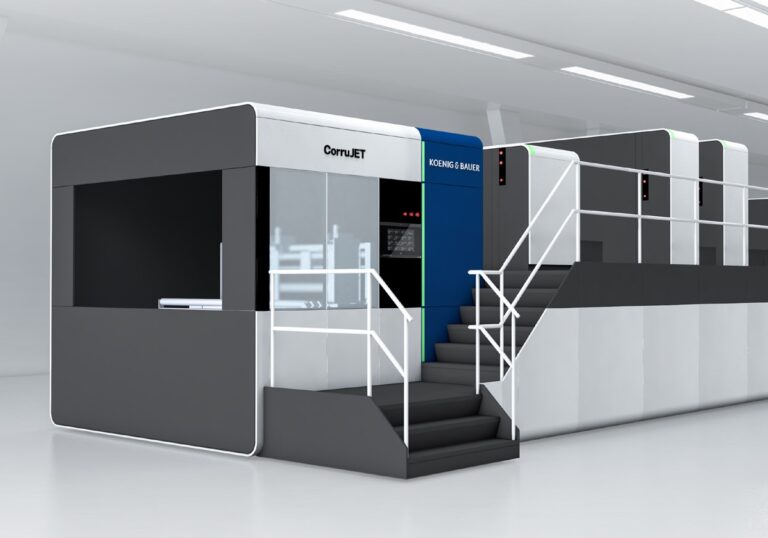

Omega Magnus, specialty folder gluer for corrugated is presented to the market in 2 sizes; 210 – 230. Magnus has a maximum belt speed of 300 metres per minute and processes E, B, C and double wall board, utilising a servo back folding system with a single finger for 4 and 6 corner styles as well as being able to handle standard straight line and auto bottom functions.