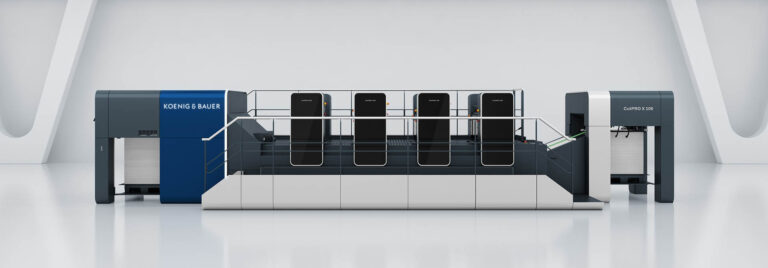

Flatbed Die-Cutters

- The versatility of the Ipress PRO series gives the possibility to die-cut several types of substrate including paper, plastic, board and corrugated material.

- The comprehensive range of optional equipment allows the configuration of the “perfect” die-cutter giving our customers the ideal machine for all of their requirements in the packaging industry.

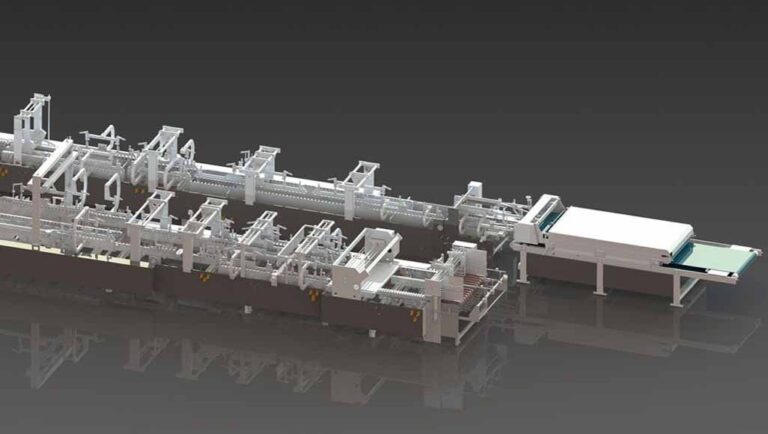

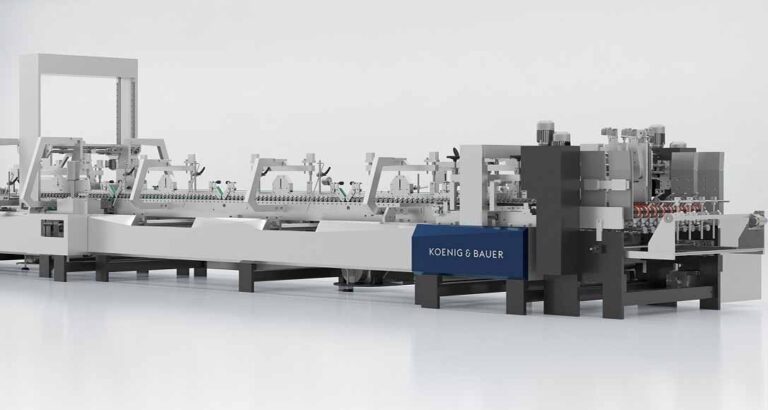

- The new blanker Ipress 106 K PRO is the most technologically advanced blanker for customers who look for high speed production perfectly combined with an exceptional registration, high quality standards and easy handle and fast preparation.