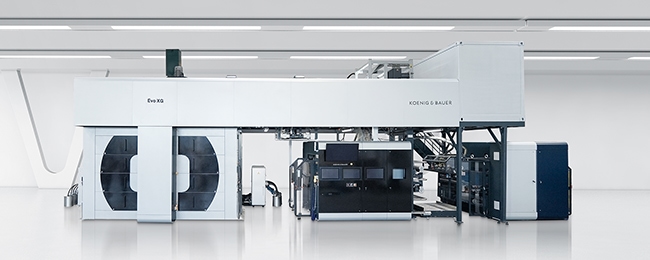

Flexo Print

- HBL technology with fixed modules and printing from below

- Siemens servo drive technology

- Quick Set Up & on the Run Changeover

- Competitive operating costs and fast return on investment

- Remote maintenance and faults diagnostic

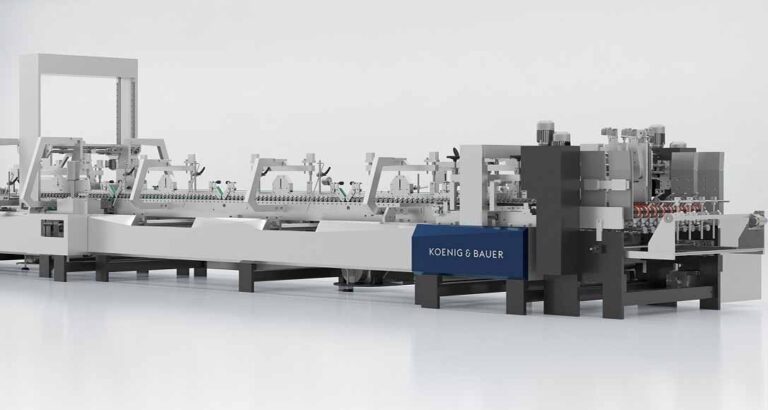

Handling a wide range of substrates from cartonboard to corrugated, OMEGA Allpro gluers are extremely versatile and capable of producing the most complex range of carton styles minimizing make ready and maximizing productivity and profitability.

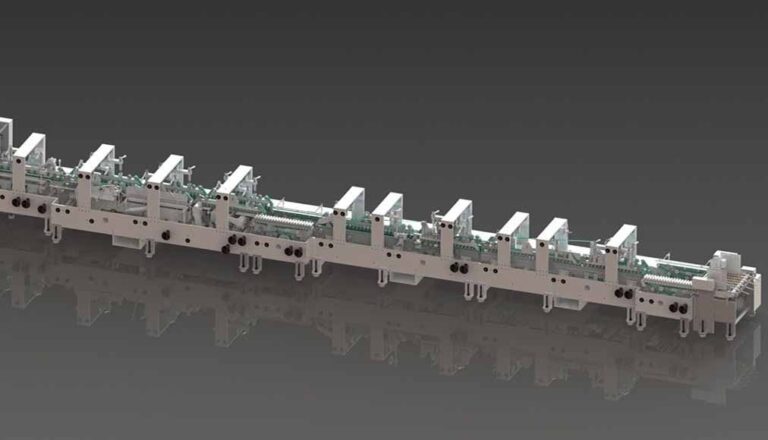

Omega Magnus, specialty folder gluer for corrugated is presented to the market in 2 sizes; 210 – 230. Magnus has a maximum belt speed of 300 metres per minute and processes E, B, C and double wall board, utilising a servo back folding system with a single finger for 4 and 6 corner styles as well as being able to handle standard straight line and auto bottom functions.

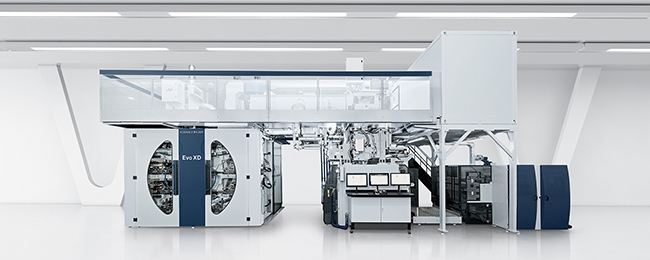

The Liquitec Phoenix is the most advanced flame sealer with skiving and hemming ability in the world today. State of the art touch screen controls give the operator all the process information required to run high speed aseptic liquid packaging cartons to the most accurate tolerances achievable. The Phoenix is capable of running a wide range of carton sizes (from minis to 5 liter) incorporating the use of linear bearings, frictionless bearings and zero backlash adjusting screws for its carriers.

OMEGA Intro series is specifically designed as a high quality budget line to be a reliable profit center for many years to come. Like all Koenig & Bauer Duran Folder Gluers, the OMEGA Intro line is designed and manufactured at Koenig & Bauer Duran plant in Istanbul.