Description

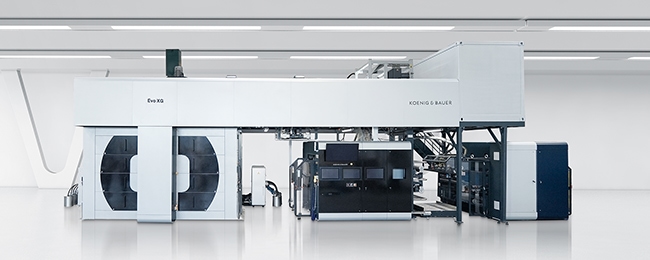

Koenig & Bauer XG

- Outstanding printing quality with a high performance level

- Systematic automation standardises work processes

- Versatility with up to 12 printing units or large printing lengths

Product Info

The XG is a highly automated flexo press for processing film sheets, paper and cardboard at production speeds of up to 600 m/min.

Systematic automation as well as sturdy and ergonomically well thought-out design allow top performance in quality and productivity. Its exceedingly smooth running, even at maximum speed, guarantees extremely stable register behaviour.

The XG can be configured for 8 or 10 printing units as standard. In the XG LR version, this CI rotary press is also available with a printing length of 1,250 mm. With the XG 12, Koenig & Bauer Flexotecnica is the only manufacturer worldwide with a CI flexo press with 12 printing units.

In all versions of the XG, solvent as well as water-based inks can be used, as well as curing inks (UV). The configuration of the XG with additional individual printing units using flexo or gravure printing technology is a further option for extending the performance range of the press. True-to-register printing, varnishing, coating or laminating in recto and / or verso printing are thus possible.

Automation and innovative technology guarantee top performance

The Evo XG is the “high end” flexo press which also guarantees top-level in-line processes. The integration of additional individual printing units using flexo or gravure printing technology also allows the in-line processing of complex printing tasks. True-to-register printing, varnishing, coating and laminating in recto and / or verso printing thus extend the performance range of the Evo XG. A wide range of automatic reelstands with reel diameters from 800 mm to 1,500mm (with winding shaft or shaftless) allow optimum, customer-specific press configuration.

The Evo XG module has many tools to meet the requirements of everyday production, rationally and reproducibly. The “Safe Sleeve Change” function makes it possible to change anilox roller and printing forme sleeves in printing units that are not currently in use while production is running. Some of the necessary set-up operations for a follow-up print job can thus be carried out while production is running. The “Smart Ride System” is a lift system equipped with sleeve trolleys for changing sleeves fast, safely and comfortably, in the upper printing units as well.

In the “pipeless” doctor chamber, the ink supply lines are routed outside the side frames. This means unrestricted access to the doctor chambers and the intermediate dryers. Setup and cleaning processes are thus significantly simplified.

WashTronic

Automatic printing unit washing system with digital control of all washing cycles by means of a touchscreen.

Features

- Outstanding printing quality with a high performance level

- Systematic automation standardises work processes

- Versatility with up to 12 printing units or large printing lengths

Specs

Standard | Optional | |

Printing units | 8 | 10/12 |

max. print width | 1,200 – 1,800 mm | 2,000 mm |

Print cylinder repeat max. | 1,000 mm | 1,250 mm |

max. web speed | 600 m/min | Higher speed available upon request |

Web width | 1,250 – 1,850 mm | 2,050 mm |

Colour systems | Solvent-based, water-based | UV |

Reelstand | 1,000 / 1,300 / 1,500 mm | Larger diameters upon request |