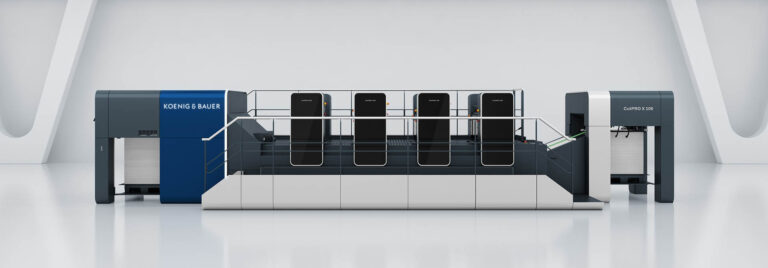

Sheetfed Offset

- Changing all plates in under 1 minute

- Simultaneous washing processes

- Unique Sensoric Infeed System (DriveTronic SIS)

- Highly flexible and customisable configurations of up to 10 units plus coater

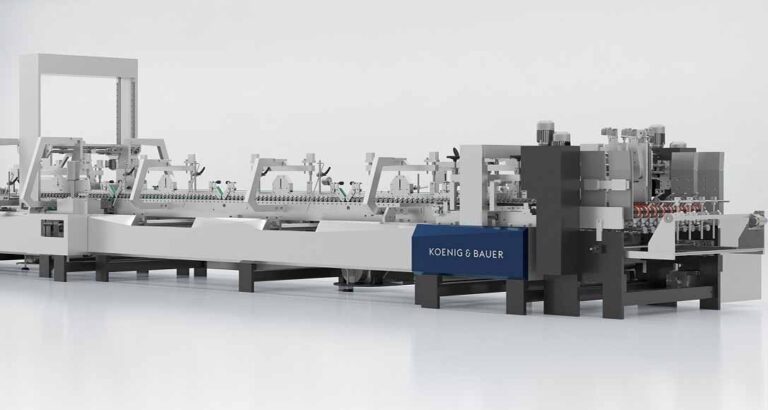

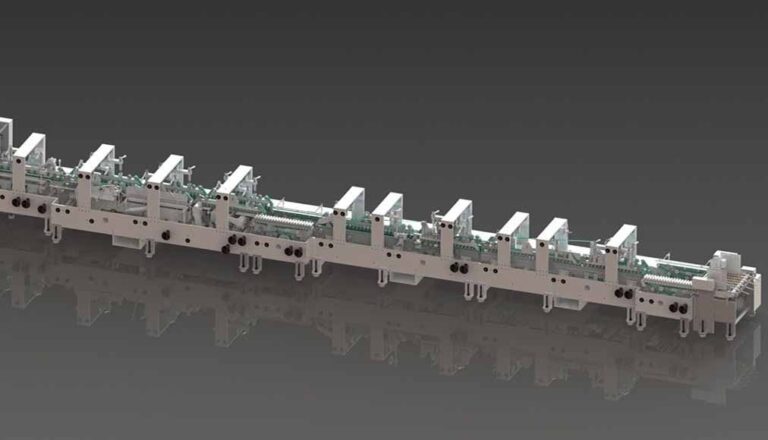

Handling a wide range of substrates from cartonboard to corrugated, OMEGA Allpro gluers are extremely versatile and capable of producing the most complex range of carton styles minimizing make ready and maximizing productivity and profitability.

The Liquitec Phoenix is the most advanced flame sealer with skiving and hemming ability in the world today. State of the art touch screen controls give the operator all the process information required to run high speed aseptic liquid packaging cartons to the most accurate tolerances achievable. The Phoenix is capable of running a wide range of carton sizes (from minis to 5 liter) incorporating the use of linear bearings, frictionless bearings and zero backlash adjusting screws for its carriers.