Description

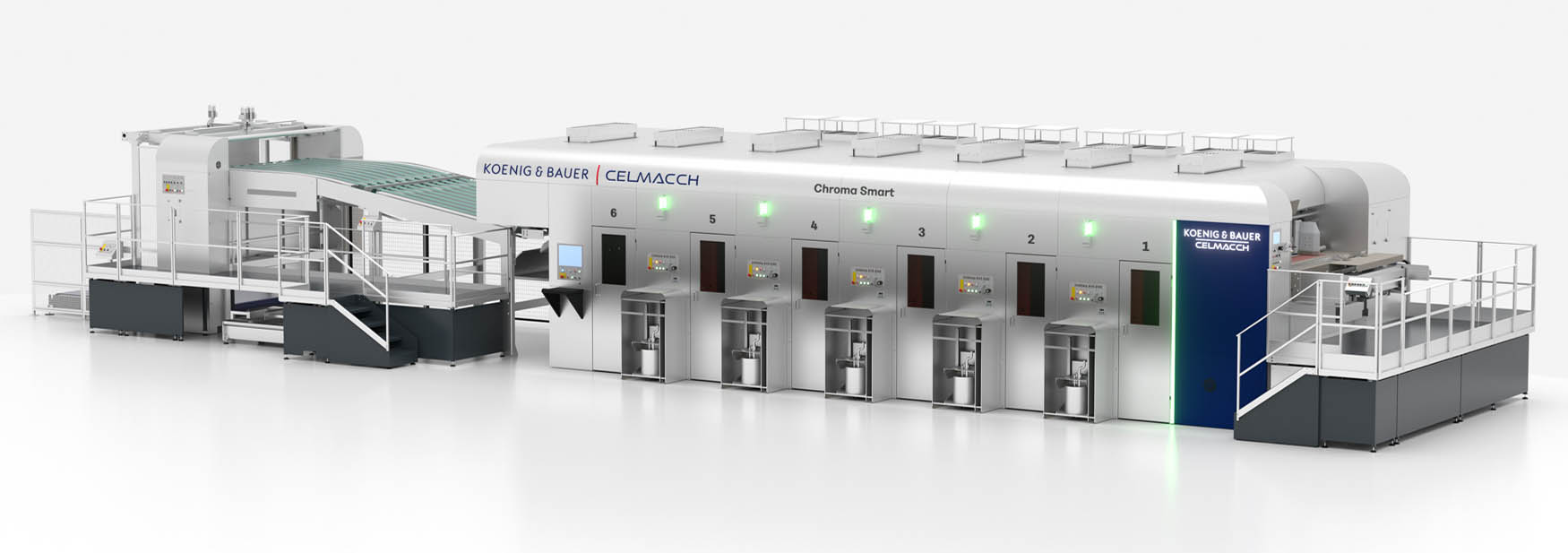

Koenig & Bauer ChromaCUT Smart

- HBL technology with fixed modules and printing from below

- Siemens servo drive technology

- Quick Set Up & on the Run Changeover

- Competitive operating costs and fast return on investment

- Remote maintenance and faults diagnostic

Product Info

Within our range of high definition flexo printers, ChromaCUT Smart represents a perfect combination of innovation and functionality. This model has been designed for those businesses in search of a solution that is not necessarily as sophisticated as the ChromaCUT High Tech, but without compromises in terms of print quality, die cutting precision and productivity.

High precision rotary die cutter with direct drive motors: the rotary module, extremely precise and robust, is equipped with Koenig & Bauer Celmacch’s quality control system. A high-spec bundle vacuum stripping stacker completes the machine, featuring high dynamic non-stop system to guarantee perfect sheet cleaning and stacking.

Developed to meet the highest expectations and European quality standards.

The mechanical parts are all made in Italy, whilst all electronic components and direct drive motors are provided by Siemens. Any other components are all supplied by the best European manufacturers. The machine is completely assembled in Italy at Koenig & Bauer Celmacch’s facility in Desenzano del Garda, guaranteeing the highest levels of reliability in the long term.

Features

- Operator controls on the left is the standard set up, but operator controls on the right is also available

- Excellent and consistent precision thanks to Direct-Drive technology

- Ultra-precision vacuum transport system with direct drive motors and extremely precise driving belts

- Carbon fibre chambered doctor blade system

- Automatic high efficiency washing system

- Siemens' PROFINET technology

- Each printing press is driven by several SIEMENS independent motors

- Koenig & Bauer Celmacch drying system double action (IR + Hot Air) available on request

- Video based quality control system 100% to detect any defects with automatic expulsion of faulty sheets

- The automation system is completely implemented according to Siemens' PROFINET standards (Industrial Ethernet) and is characterized by flexibility, reliability, roboustness and high transmission speed

- The use of connected devices within PROFINET improves the diagnostic process in case of faults, even remotely thanks to direct contact with Koenig & Bauer Celmacch's specialised technicians

Specs

Model | Chroma Smart 1700 | Chroma Smart 2100 | ||

Sheet width | Max 1700 mm Min 550 mm | Max 2100 mm Min 550 mm | ||

Sheet length | Max 1280 mm / Min 520 mm | |||

Maximum printing size | 1700X1300 mm | 2100X1300 mm | ||

Maximum mechanical speed | 9000 sheets/hour | |||

Ø Stereo-Holdercylinder | 448,17 mm (with stereo) | |||

Processed materials | F, E, A, B, C, AB, AC, BC, EB, EF | |||

Corrugated board | Thickness of 1 to 8 mm | |||

Solid board | Thickness of 1 to 3 mm | |||