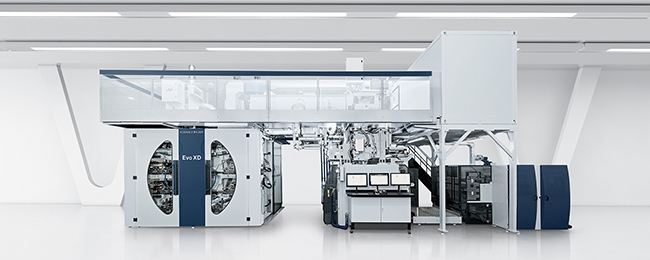

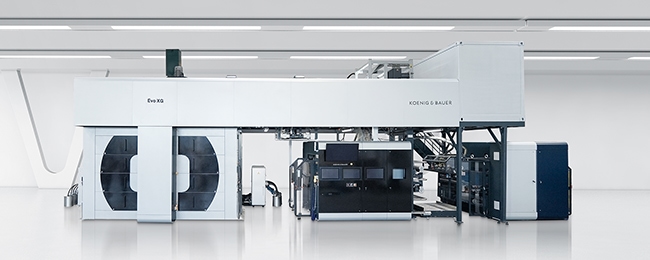

Sheetfed Offset

- Production speed up to 18,000 sheets/h

- Suitable for a particularly wide range of substrates

- Sidelay-free infeed DriveTronic SIS

- AniloxLoader and DriveTronic SFC

- Modern operating concept with touch panels and apps

OMEGA Intro series is specifically designed as a high quality budget line to be a reliable profit center for many years to come. Like all Koenig & Bauer Duran Folder Gluers, the OMEGA Intro line is designed and manufactured at Koenig & Bauer Duran plant in Istanbul.